Coal Seam Gas

Coal Seam Gas

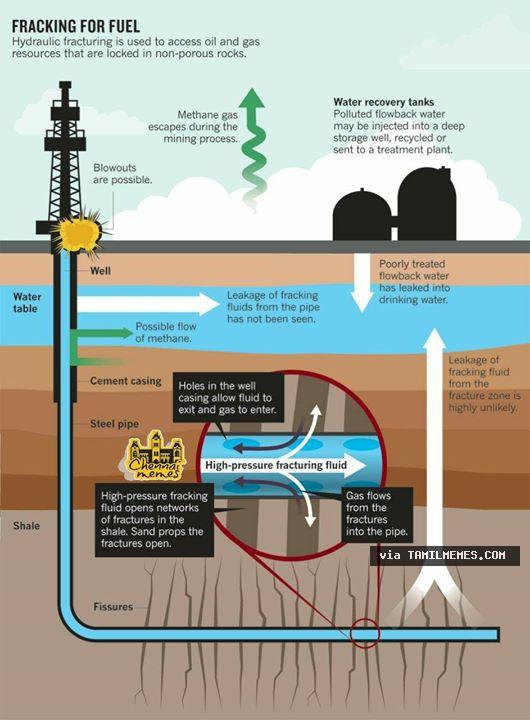

Coal Seam Gas (CSG) is a naturally mostly methane gas found in most coal seams. Generally it is extracted from coal seam at depths of 100 to 300m by drilling down into the coal seam then drillinh horizontally along the length of the seam. The gas is released from the rock by fracturing called "fracking" this can be done in a number of ways, using explosives , pressurised water and proprietary and BTEX fracking fluids.

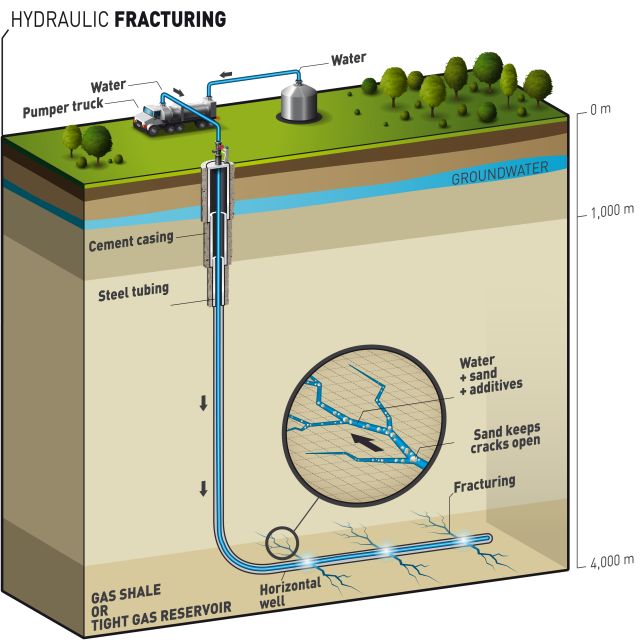

How is hydraulic fracturing carried out?

Hydraulic fracturing, also commonly referred to as fracking, is a method used by the oil and gas industry since the late 1940s to increase the rate and total amount of oil and gas extracted from reservoirs. It has been used to enhance coal seam gas (CSG) production from coal seams since the 1970s in the United States (US) and since the 1990s in Australia. Increased CSG activity, mostly in Queensland and New South Wales, has caused a parallel increase in the use of hydraulic fracturing. Although the technological aspects of hydraulic fracturing are known, the environmental impacts of hydraulic fracturing are less well characterised.

Typically, a well is fully cased from top to bottom with steel casing. To gain access to the coal, the casing is perforated at specific intervals along the well, where the fracture treatment is to be carried out. Hydraulic fracturing typically involves injecting fluid made up of water, sand and chemical additives under high pressure into the cased well. The pressure caused by the injection typically creates a fracture in the coal seam where the well is perforated.

For a large CSG treatment, the fracture might typically extend to a distance of 200 to 300 metres from the well. The fractures grow slowly.

For example, an average velocity may be less than 10 metres per minute initially and slowing to less than one metre per minute at the end of the treatment. The sand in the hydraulic fracturing fluid acts to keep the fracture open after injection stops, and forms a conductive channel in the coal through which the water and gas can travel back to the well. After the fracturing is complete, most of the hydraulic fracturing fluid is, over time, brought back to the surface and treated before being used again or disposed of.

The nature of an individual hydraulic fracture is complex, and depends on various factors such as the nature of land use in surrounding areas, geology, and hydrodynamics. Why is hydraulic fracturing used? Without the recent and significant technological advances made in drilling and hydraulic fracturing, a portion of the natural gas found in coal seams would be uneconomic and unrecoverable. Hydraulic fracturing is the most common method used to increase the production from a CSG well, but not all gas wells require hydraulic fracturing.

What does the hydraulic fracturing fluid contain?

Generally only wells that intersect lower permeability coal seams require hydraulic fracturing and these are usually deeper seams. In Australia the technique is used in approximately 20–40 per cent of CSG wells. Water (84 to 96 per cent) proppant (3 to 15 per cent), such as sand, make up around 99 per cent of the hydraulic fracturing fluid.

Added chemicals make up about 1 per cent of the hydraulic fracturing fluid.

Some commonly used chemical additives, and their uses in hydraulic fracturing fluids, include:

- guar gum (a food thickening agent) is used to create a gel that transports sand through the fracture

- bactericides, such as sodium hypochlorite (pool chlorine) and sodium hydroxide (used to make soap), are used to prevent bacterial growth that contaminates gas and restricts gas flow

- ‘breakers’, such as ammonium persulfate (used in hair bleach), that dissolve hydraulic fracturing gels so that they can transmit water and gas surfactants, such as ethanol and the cleaning agent orange oil, are used to increase fluid recovery from the fracture

- acids and alkalis, such as acetic acid (vinegar) and sodium carbonate (washing soda) to control the acid balance of the hydraulic fracturing fluid.

- some hydraulic fracturing fluids may also contain chemicals that are not commonly associated with domestic use (e.g cyclohexylamine; Ethylene diaminetetra acetic acidtetrasodium salt [EDTA]).

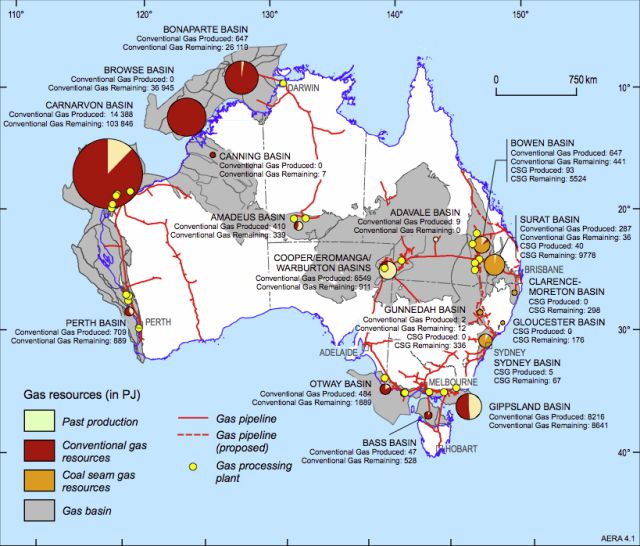

Where has hydraulic fracturing been used in Australia?

Hydraulic fracturing has been widely used in Australia within the geothermal and gas industries. Hydraulic fracturing for stimulation of petroleum wells, as distinct from CSG wells, has been used in most states, with the bulk of activity in South Australia and Queensland. Fracturing for stimulation of CSG wells has been carried out mostly in Queensland and New South Wales. How much In Australia the commercial production of CSG commenced in 1996 in the Bowen Basin, Queensland. Since then production has increased rapidly, particularly during the first decade of the 21st century. CSG has now become an integral part of the gas industry in eastern Australia, particularly in Queensland. Information about reserves of CSG has grown significantly, particularly in the Bowen and Surat basins in Queensland.

In New South Wales reserves have been proven in the Sydney, Gunnedah, Clarence-Moreton and Gloucester basins. Exploration has been undertaken or is planned to be undertaken in other coal basins including the Galilee, Arckaringa, Perth and Pedirka basins. A major driver for the growth in CSG was a decision in 2000 by the Queensland Government that required 13% of all power supplied to the state electricity grid to be generated by gas by 2005. That requirement has been increased to 15% by 2010 and 18% by 2020. CSG reserves have grown to such an extent that a number of Liquid Natural Gas (LNG) plants have been proposed based on exports from Gladstone, Queensland.