In Situ Uranium Leach Mining

In Situ Uranium Leach Mining

In Situ Leach Mining

What is ISL and How long has it been used?

ISL Uranium Deposit Characteristics

ISL Wellfield -an overview

Uranium Recovery

ISL in Australia

Environment & Health

sources

see also Australian Uranium Deposits

In Situ Leach Mining

Most uranium mining in USA is now by in situ leach (ISL) methods. In USA it is seen as the most cost effective and environmentally acceptable method of mining. There are two proposals well advanced for ISL mining of uranium in Australia.

Conventional mining involves removing rock from the ground, breaking it up and treating it to remove the minerals being sought.

What is ISL and How long has it been used?

In situ leaching (ISL), also known as solution mining, involves leaving the ore where it is in the ground, and using liquids which are pumped through it to recover the minerals out of the ore by leaching. Consequently there is little surface disturbance and no tailings or waste rock generated. However, the orebody needs to be permeable to the liquids used, and located so that they do not contaminate ground water away from the orebody.

ISL mining was first tried on an experimental basis in Wyoming during the early 1960s. The first commercial mine began operating in 1974. Today about a dozen projects are licensed to operate in the USA, (in Wyoming, Nebraska and Texas) and most of the operating mines are less than 10 years old. Most are small, by Australian standards but they supply some 85% of the US uranium production. About 13% of world uranium production is by ISL (including all Kazakhstan and Uzbekistan output).

ISL can also be applied to other minerals such as copper and gold.

ISL Uranium Deposit Characteristics

Uranium deposits suitable for ISL occur in permeable sand or sandstones, confined above and below by impermeable strata and below the water table. They may either be flat, or "roll front",- in cross section, C-shaped deposits within a permeable sedimentary layer.

They were formed by the lateral movement of groundwater bearing oxidised uranium minerals through the aquifer, with precipitation of the minerals occurring when the oxygen content decreased, along extensive oxidation-reduction interfaces. The uranium minerals are usually uraninite (oxide) or coffinite (silicate) coatings on individual sand grains. The ISL process essentially reverses this ore genesis, in a much shorter time frame.

Techniques for ISL have evolved to the point where it is a controllable, safe, and environmentally benign method of mining which can operate under strict environmental controls and which often has cost advantages.

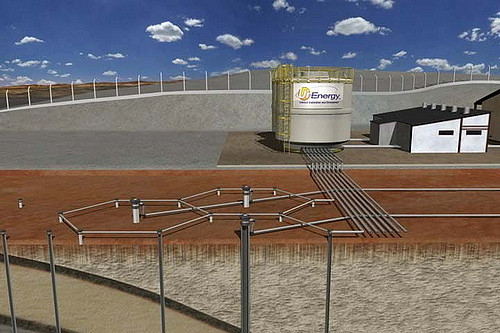

ISL Wellfield -an overview

Wells are cased to ensure that liquors only flow to and from the ore zone. Submersible electric pumps draw from near the bottom of the production wells.

A wellfield design is typically a grid with alternating production and injection wells. The spacing between them usually ranges from 15 to 30 metres. A series of monitor wells are situated around the whole wellfield to ensure that contaminated water does not move outside the mining area.

Oxygen is injected into the leach liquors as they are returned to the injection wells and drawn into the ore zone to oxidise the uranium minerals. They are then removed as the liquors are pumped out.

While uranium production in Australia uses acid leaching of the crushed ore, ISL overseas normally uses alkaline leaching agents such as a combination of sodium bicarbonate and carbon dioxide. At Honeymoon in SA, the process will be acid leaching with weak sulfuric acid plus oxygen. The leaching solution is at a pH of 2.8 - 2.0, about the same as vinegar.

In USA the production life of an individual ISL wellfield is usually less than 3 years, typically 6-10 months. Most of the uranium is recovered during the first 6 months of the wellfield's operation. The most successful operations have achieved a total overall recovery of about 80% of the ore. Over time, production flows decrease as clay and silt become trapped in the permeable sediments. These can be dislodged to some extent by using higher-pressure injection or by reversing the flow between injection and production wells.

Uranium Recovery

The pregnant solution from the production wells is pumped to the treatment plant where the uranium is removed from it in an ion exchange system; or by solvent extraction. The uranium is then stripped from the ion exchange resin, and precipitated chemically.

Most of the solution is returned to the injection wells, but a little is bled off and treated as wastewater. It contains various dissolved minerals such as radium, arsenic and iron. Barium chloride is added to precipitate the radium. This bleed of process solution ensures that there is a steady flow into the wellfield from the surrounding aquifer, rather than having any leach liquor move in the other direction. Before the process solution is reinjected, it is oxygenated and if necessary recharged with sodium bicarbonate or acid.

ISL in Australia

Two projects are currently proposed for ISL mining operations in Australia; Honeymoon and Beverley, both in the Lake Frome area of South Australia between Broken Hill and the northern Flinders Ranges.

At Honeymoon the uranium deposit occurs in porous sandstone at a depth of 100 to 120 metres and extending over about 24 hectares of a buried riverbed (palaeochannel).

Honeymoon was discovered in 1972, about 75 kilometres north west of Broken Hill. Early in 1997 Sedimentary Holdings NL reached agreement with MIM Holdings Ltd to acquire the Honeymoon and two adjacent uranium deposits next to its own Chatfield (East Kalkaroo) deposits.

This brings together uranium resources of about 6800 tonnes U3O8 averaging 0.15% and amenable to ISL. The purchase was funded by Southern Cross Resources Inc. of Toronto which raised funds in Canada for the development of the SA uranium properties. Sedimentary Resources (an Australian company) holds 35% of Southern Cross.

Plans had been developed in the 1970s to extract the uranium oxide by ISL, and some $12 million was spent in preparation then. Draft and Final Environmental Impact Statements were produced, and both South Australian and Commonwealth environmental approval was subsequently obtained in 1981 for production to 450 t/yr. Field tests of the in situ leaching process were carried out and a $3.5 million, 110 t/yr pilot plant was built and remains on site, but the project was abandoned in 1983*.

Southern Cross now plans to bring Honeymoon and the associated deposits into production in 1998, building up to 450 tonnes per year by 2000.

The Beverley deposit, 520 kilometres north of Adelaide is northwest of Honeymoon and geologically similar to it. Plans to mine it by ISL were abandoned in 1983 when the South Australian Government refused to grant permission for development to proceed*. The deposit was sold to Heathgate Resources Pty Ltd, an affiliate of General Atomics of USA, in 1990.

Three ore lenses lie at a depth of 110-140 metres, over some 4 km. Their 6 million tonnes of 0.27% ore contains 16 200 tonnes of uranium oxide. An estimated 11 500 tonnes of this was considered recoverable by ISL at 900 tonnes per year, making it the largest Australian deposit of its kind.

Hydrogeological tests and operation of a continuous field leach trial are being undertaken in 1997-98, along with preparation of a new Environmental Impact Statement. Heathgate Resources is working towards commencing production before 2000.

Environment & Health

At established operations overseas, after ISL mining is completed, the quality of the remaining groundwater must be restored to a baseline standard determined before the start of the operation, so that any prior use can be resumed. Contaminated water drawn from the aquifer is either evaporated or treated before reinjection.

In contrast to the main US operations, the water quality at the Australian sites is very low to start with, and it is quite unusable. At Beverley the groundwater in the orebody is very saline and orders of magnitude too high in radionuclides for any permitted use. At Honeymoon the water is similarly very saline, and high in sulfates and radium. When acid leaching is discontinued, the water quality reverts to its original condition.

Upon decommissioning, wells are sealed or capped, process facilities removed, any evaporation pond revegetated, and the land can readily revert to its previous uses.

The usual radiation safeguards are applied at an ISL mining operation, despite the fact that most of the orebody's radioactivity remains well underground and there is hence no increase in radon release and no ore dust. Employees are monitored for alpha radiation contamination and personal dosimeters are worn to measure exposure to gamma radiation. Routine monitoring of air, dust and surface contamination are undertaken.

- due to the ALP "3 mines" policy

SOURCES

Brunt, D, 1997; Proposed in situ leach mining at Beverley, SA; Uranium '97 conference, Darwin. Dobrzinski, I, 1997, Beverley and Honeymoon Deposits, MESA Journal 5, April 1997. Szymanski, W N. 1993, Energy

Information Administration, Uranium Industry Annual. Uranium Institute, 1996, Global Nuclear Fuel Market,supply & demand 1995-2015.